| Find Louisiana State Museum on Facebook |

| Find Louisiana State Museum on Twitter |

| 2016 Sunset Report |

| OLG & DCRT Strategic Plan 2020-21 through 2024-25 |

- Quality - Louisiana State Library

85% of the users of the State Library indicated that the State Library's services and resources was a good value for the State.Source: The Impact of the Louisiana Department of Culture, Recreation and Tourism on Louisiana's Economy and Quality of Life for Louisiana's Citizens - June 2006

- Louisiana's deep water ports

Did you know that Louisiana's five deep water ports handle more than 457 million tons of U.S. waterborne commerce a year? - Quality - Louisiana State Library

85% of the users of the State Library indicated that the State Library's services and resources was a good value for the State.Source: The Impact of the Louisiana Department of Culture, Recreation and Tourism on Louisiana's Economy and Quality of Life for Louisiana's Citizens - June 2006

- Atchafalaya Heritage Area

The Atchafalaya Heritage Area has been designated by Congress as a National Heritage Area.

- Impact - DCRT Returns Investment Dollars to Louisiana

For every state tax dollar spent by the Department of Culture, Recreation and Tourism, $5.86 is returned to the State Treasury and citizens of Louisiana.Source: The Impact of the Louisiana Department of Culture, Recreation and Tourism on Louisiana's Economy and Quality of Life for Louisiana's Citizens - June 2006

- Impact - Louisiana Office of Tourism Tops Returns on Investment

$13.90 is the return on investment for every dollar spent by the Office of Tourism. Over 175,000 people were directly employed by the Louisiana travel and tourism industry in 2004. In terms of production, $5.9 billion (3.8%) of Louisiana's Gross State Product was directly attributable to expenditures by visitors to LouisianaSource: The Impact of the Louisiana Department of Culture, Recreation and Tourism on Louisiana's Economy and Quality of Life for Louisiana's Citizens - June 2006

- Impact - Supporting the Louisiana Arts

Every dollar in state support for the Arts leverages $7 in earned and contributed revenue. Louisiana's cultural enterprises provide nearly 144,000 jobs for Louisiana citizens, accounting for 7.6% of total employment. Arts has a total economic impact of $934 million in Louisiana.Source: The Impact of the Louisiana Department of Culture, Recreation and Tourism on Louisiana's Economy and Quality of Life for Louisiana's Citizens - June 2006

- Impact - Visitors Generate State Revenue

In terms of tax revenues, visitor spending accounted for $677 million of 2004 Louisiana revenues, or 8.3% of the total 2004 State Budget.Source: The Impact of the Louisiana Department of Culture, Recreation and Tourism on Louisiana's Economy and Quality of Life for Louisiana's Citizens - June 2006

- Quality - Louisiana State Museums

95% of State Museum's visitors strongly agreed or agreed that the State Museum was an educational experience and has expanded their awareness of Louisiana's cultural history.Source: The Impact of the Louisiana Department of Culture, Recreation and Tourism on Louisiana's Economy and Quality of Life for Louisiana's Citizens - June 2006

- Quality - Historic Preservation and the Arts

78-80% of Louisiana residents believe that historic preservation and arts are important and should be high priorities.Source: The Impact of the Louisiana Department of Culture, Recreation and Tourism on Louisiana's Economy and Quality of Life for Louisiana's Citizens - June 2006

- Impact - Louisiana Serve Program

The Louisiana Serve Program in the Office of Lieutenant Governor returns 2.8 million in non-state revenue to Louisiana. - Impact - Louisiana State Museum

The Office of State Museum returns $6.99 for every tax dollar spent.Source: The Impact of the Louisiana Department of Culture, Recreation and Tourism on Louisiana's Economy and Quality of Life for Louisiana's Citizens - June 2006

- Impact - Louisiana State Parks

Visitor spending at Louisiana State Parks returns $3.23 in state taxes for every dollar spend on operating and maintaining all our beautiful parks. Out-of-state visitors to Louisiana State Parks spent almost $12 million in Louisiana and produced an economic impact of over $24 million. Louisiana residents spent another $29.2 million while visiting the parks.Source: The Impact of the Louisiana Department of Culture, Recreation and Tourism on Louisiana's Economy and Quality of Life for Louisiana's Citizens - June 2006

- Impact - Scenic Byways Program

The Scenic Byways program leverages $1.56 for every dollar spent by the program.Source: The Impact of the Louisiana Department of Culture, Recreation and Tourism on Louisiana's Economy and Quality of Life for Louisiana's Citizens - June 2006

- Louisiana State Parks and the National Register

Thirteen Louisiana State Parks sites are on the National Register of Historic Places. They include:

• Audubon State Historic Site

• Centenary State Historic Site

• Fort Pike State Historic Site

• Fort Jesup State Historic Site

• Longfellow-Evangeline State Historic Site

• Mansfield State Historic Site

• Marksville State Historic Site

• Plaquemine Lock State Historic Site

• Port Hudson State Historic Site

• Poverty Point State Historic Site

• Otis House at Fairview-Riverside State Park

• Rosedown Plantation State Historic Site

• Winter Quarters State Historic Site - Louisiana State Parks Visitation

Nearly two million people visited a Louisiana State Park last year. - Louisiana State Parks Grow and Renew

The Louisiana Office of State Parks has spent nearly $80 million in major construction projects since 2004, providing two brand-new parks and a new historic site, adding cabins and campsites to existing parks and building visitor center at one park, the preservation area and three historic sites. - Louisiana State Parks Wireless Internet

The Louisiana Office of State Parks provides free wireless internet access at all 20 recreational parks. Extensive coverage areas include most cabins, RV slips and campsites. - Louisiana State Parks Online Reservations

You can now make online reservations for cabins, campsites, lodges and group camps – at www.ReserveLaStateParks.com - Louisiana State Parks Honors National Parks Service Senior Pass Program

Visitors who hold an America the Beautiful Senior or Access Pass, and whose home State Park system honor the America the Beautiful passes for camping discounts, are entitled to a 50% reduction on camping fees at Louisiana State Parks. Certain restrictions apply, see State Parks' fees & facilities page for more information. - Louisiana State Parks Draw Media Attention

Louisiana State Parks sites have been featured in movie and television releases including "True Detective," CBS’ "Zoo," and "NCIS: New Orleans," "G.I. Joe: Retaliation," "Selfless," "Devil’s Due," and commercials for Popeyes and Toyota. - Capitol Park Welcome Center

The main meeting room in the Capitol Park Welcome Center is named after Margaret Taylor, wife of U.S. President Zachary Taylor. The couple resided in a small house near the present day location of Capitol Park until Taylor was elected to the Presidency.

| Introduction | Section 1: Cultural Assumption |

Section 2: Ethnographic Record |

Section 3: Plagiary |

Section 4: Political Instrument |

| Section 5: History |

Section 6: Art & Craft |

Section 7: Papermaking |

Biographies of Mapmakers & Artists | Bibliography |

Many people find it remarkable that maps have survived for over three or four hundred years. Most early maps were printed on strong, thick, paper handmade in France, Germany, Switzerland, and, after 1610, England; the finest paper came from northern Italy. The size of paper on which maps were printed was determined by the size of the printing press. Large maps were made by individually printing the sheets and then gluing them together.

Paper was first made in Asia about two thousand years ago, and the art of papermaking evolved gradually. More than a thousand years passed before it was introduced into Europe during the thirteenth century. There, paper was produced almost entirely from linen and cotton rags pulped in water. Papermaking required a long and often expensive apprenticeship. Workers were frequently sworn to secrecy because no craftsman wished to share knowledge with competitors.

After pulped fibers were thoroughly mixed in a deep vat, a wire mesh tray was dipped into the mixture and a sufficient amount lifted out to yield the required thickness of paper. A wooden frame called a deckle fitted over the tray to form a raised edge and prevented the watery pulp from escaping. Pulp flowing between the frame and the deckle produced an irregular feathery edge around the paper hence the term "deckle-edged" paper. As soon as possible the newly formed sheet of paper was removed from the tray and placed between two pieces of felt. The paper-and-felt "sandwiches" were then pressed to remove surplus water and the paper hung to dry.

click for larger image | Reproduced from Denis Diderot's Encyclopedie 1767 |

| Women graded and sorted cotton and linen rags according to quality. Gift of Friends of the Cabildo | |

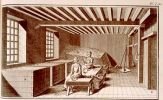

click for larger image | Reproduced from Denis Diderot's Encyclopedie 1767 |

| Sorted rags were broken down by hand-stamping the fibers. Gift of Friends of the Cabildo | |

click for larger image | Reproduced from Denis Diderot's Encyclopedie 1767 |

| Stamping mechanism used to reduce rag materials into usable fibers for papermaking. Gift of Friends of the Cabildo | |

click for larger image | Reproduced from Denis Diderot's Encyclopedie 1767 |

| Newly made paper is burnished to remove unevenness and pressed for a final time. Gift of Friends of the Cabildo | |